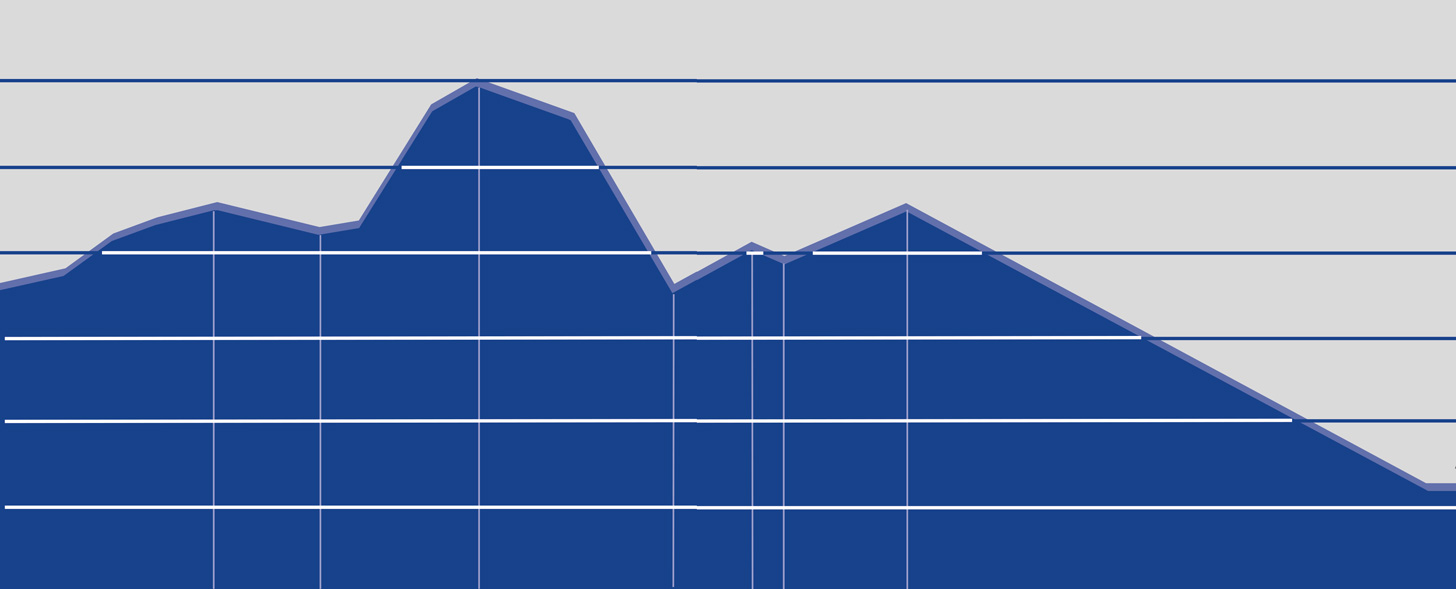

Pressure pipes with high and low points

For pneumatic wastewater conveyance systems by OEKERMANN, pressure pipelines can be cost-effectively laid parallel to the ground surface at frost-free depths.

High and low points along the route are easily overcome.

Since the wastewater is transported by compressed air and becomes enriched with oxygen, high points do not need to be vented. Drainage or cleaning openings at low points are also not necessary, as the cleaning effect is achieved through the post-purge process.

The installation of pressure pipelines is therefore cost-effective and time-saving.

The calculation of pressure pipelines – determining the most favorable pipe inner diameter as well as the geodetic and manometric pressure head for optimal system sizing – is carried out using software specifically developed by OEKERMANN.

Overcoming Large Height Differences

With OEKERMANN systems, manometric pressure heads of up to approximately 80 mWC = 8 bar can be achieved. The maximum design pressure of the systems is 100 mWC = 10 bar. All components are designed for this pressure range.

Flat Pressure Pipeline Routes

Even in flatter terrain or on routes with natural gradients, it can be sensible to use OEKERMANN compressed air systems in conjunction with low wastewater volumes or longer dry periods. Heavy solids are carried along during the post-purge process. Compared to gravity sewers, lower construction costs may result.

There are no odor nuisances or corrosion damage to structures.