Why are pneumatic wastewater pumping stations used instead of conventional pumps?

The decisive advantages of the pneumatic conveying technology System OEKERMANN are:

- no odor nuisances

- no hydrogen sulfide corrosion

- no deposits in the pressure pipeline system

- simple and cost-effective installation of pressure pipes without air release valves

- very long service life of pneumatic systems from OEKERMANN

Conventional conveying methods, e.g., using hydraulic pumping stations in wet or dry installation, are well-known and have been used for a long time. However, with low wastewater volumes and relatively long pressure pipes, especially in rural areas, the use of this conventional technology quickly reaches its limits: The wastewater decomposes in the pressure pipe, at the latest after about 3 – 4 hours without oxygen; hydrogen sulfide forms, leading to odor nuisances. In addition, hydrogen sulfide corrosion occurs on concrete, steel, and iron parts.

Putrid or decomposed wastewater cannot be biologically degraded. The negative consequences are at best mitigated by the use of chemical additives that must be dosed into the wastewater stream. However, this is cost-intensive, technically complex, and partially ineffective if dosed incorrectly. Although air injection stations can be added to the pumping station, which periodically pump compressed air into the pressure pipe; however, with such a variant, a continuous enrichment with air oxygen is not possible due to the system.

Furthermore, there are often physical-technical limits to the use of conventional pumping stations in wet or dry installation, e.g., with long pressure pipes and/or large height differences.

For these reasons, OEKERMANN developed Pneumatic Wastewater Conveyance in the 1970s. When using pneumatic wastewater conveying systems according to the system developed by OEKERMANN, the aforementioned and generally known negative effects of conventional pump technology do not occur.

The wastewater is conveyed fresh, in a perfectly treatable condition, to the treatment plant.

Clean pumping station area

This is achieved by continuously mixing the wastewater arriving at the pumping station from the gravity sewer system with air, and thus oxygen. An intensive mixing already takes place in the preliminary shaft of the OEKERMANN pumping stations. At the same time, any deposits are stirred up and floating materials are mixed into the wastewater. Odor nuisances and deposits in the pumping station and preliminary shaft area do not occur.

Electronically controllable air injection processes

Depending on local requirements, air injection processes take place periodically according to time or a variable specification.

During periods of low wastewater flow, e.g., at night, the respective pressure pipe is emptied as much as possible. Any settling heavy materials are carried along with the accelerated wastewater flow. Deposits are largely avoided.

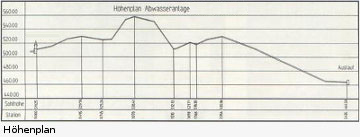

Pressure pipes with high and low points

Another significant advantage of using the OEKERMANN conveying system is that the pressure pipes are laid parallel to the top edge of the terrain, only with frost-free coverage.

Advantages:

- Simple and cost-effective installation of pressure pipes

- Additionally, the installation of air release valves at high points in the pressure pipe route can (must) be omitted.

- Savings in investment costs for shafts and fittings, reduced maintenance effort.

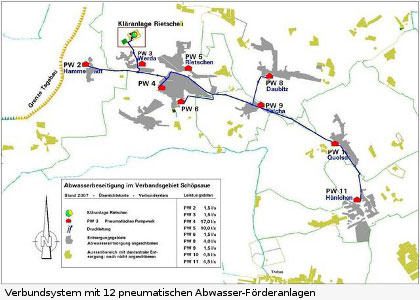

Interconnected systems

Interconnected systems can be realized in the simplest way due to the system design.

Advantages:

- Savings in investment and follow-up costs for control cables

- load-dependent conveying without mutual waiting times of the connected pneumatic pumping stations, which would otherwise occur with interlocks

Hygienic and operationally safe

OEKERMANN systems are installed dry. There are no installations in the system parts through which wastewater flows, such as float switches, probes, rods, or other mechanical or electrical components. All machine assemblies are easily accessible.

Advantages:

- no functional impairments due to foreign substances in the wastewater, especially fibrous materials, textiles, etc.

- the operating/maintenance personnel do not come into contact with wastewater. This is not only hygienic but primarily serves the health of the local personnel

- No explosion protection required, as all electrical components are installed outside of hazardous areas