Air Injection Stations to Prevent Septic Conditions and Deposits

Air Injection Stations are Mostly Used in Conjunction with Pressure Sewerage Systems These Stations Regularly Inject Compressed Air into the Pressure Pipeline. This is Intended to Prevent Septic Conditions and Deposits.

Due to the Connected Pumps, but Primarily for Energy Cost Reasons, These Systems Only Operate Periodically (Once or Maximum 3 Times per 24 Hours), Therefore Septic Conditions Cannot be 100% Prevented. However, This is Usually Accepted Because the Total Wastewater Volumes are Generally Very Low and are Sufficiently Diluted at the Treatment Plant.

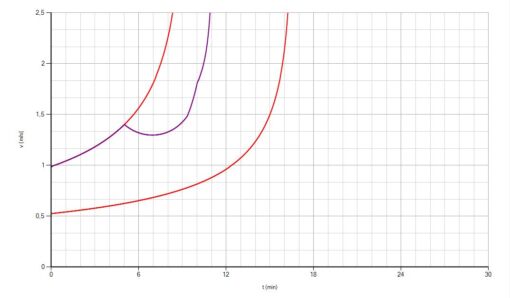

There is a Further Limitation Against This System in Interconnected Systems. Depending on the Number of Stations Operating at Any Given Time, the Manometric Pressure Can Reach or Even Exceed the Performance Limit of the Pumps Used. This Can Result in Long Running Times for Individual Stations Under Certain Circumstances. If the Air Injection Compressor is Then Started Additionally, Individual Stations May Temporarily Experience Zero Flow, Despite Full Energy Consumption.

As Already Explained for Pressure Sewerage Systems, the ‘Pneumatic Wastewater Conveyance’ System Can be Considerably More Advantageous Than the Combination of Pumps and Air Injection Compressor.

Further Information is Available on This, and We Would be Happy to Advise You on a Specific Project.

Unlike the Combination with Pumps = Pressure Sewerage System, Compressed Air Flushing Stations are Also Used for Gravity-Flow Siphon Sections, but There Mainly to Stir Up and Further Transport Heavy Solids That Have Settled in Low Points.

Odor Nuisances for Residents Do Not Occur. Hydrogen Sulfide Corrosion on Concrete and Iron/Steel Structures in the Sewer Network or at the Treatment Plant are Reliably Prevented.